Дызайн заводаў і жылых памяшканняў Сталёвыя канструкцыі Метал

Сталёвая канструкцыя— гэта канструкцыя, якая складаецца са сталёвых матэрыялаў і з'яўляецца адным з асноўных тыпаў будаўнічых канструкцый. Канструкцыя ў асноўным складаецца са сталёвых бэлек, сталёвых калон, сталёвых канструкцый і іншых кампанентаў, вырабленых з профільнай сталі і сталёвых лістоў, і праходзіць праз сіланізацыю, фасфатаванне чыстым марганцам, мыццё і сушку, ацынкаванне і іншыя працэсы прадухілення іржы.

*У залежнасці ад вашага прымянення, мы можам распрацаваць найбольш эканамічную і трывалую сістэму сталёвага каркаса, каб дапамагчы вам стварыць максімальную каштоўнасць для вашага праекта.

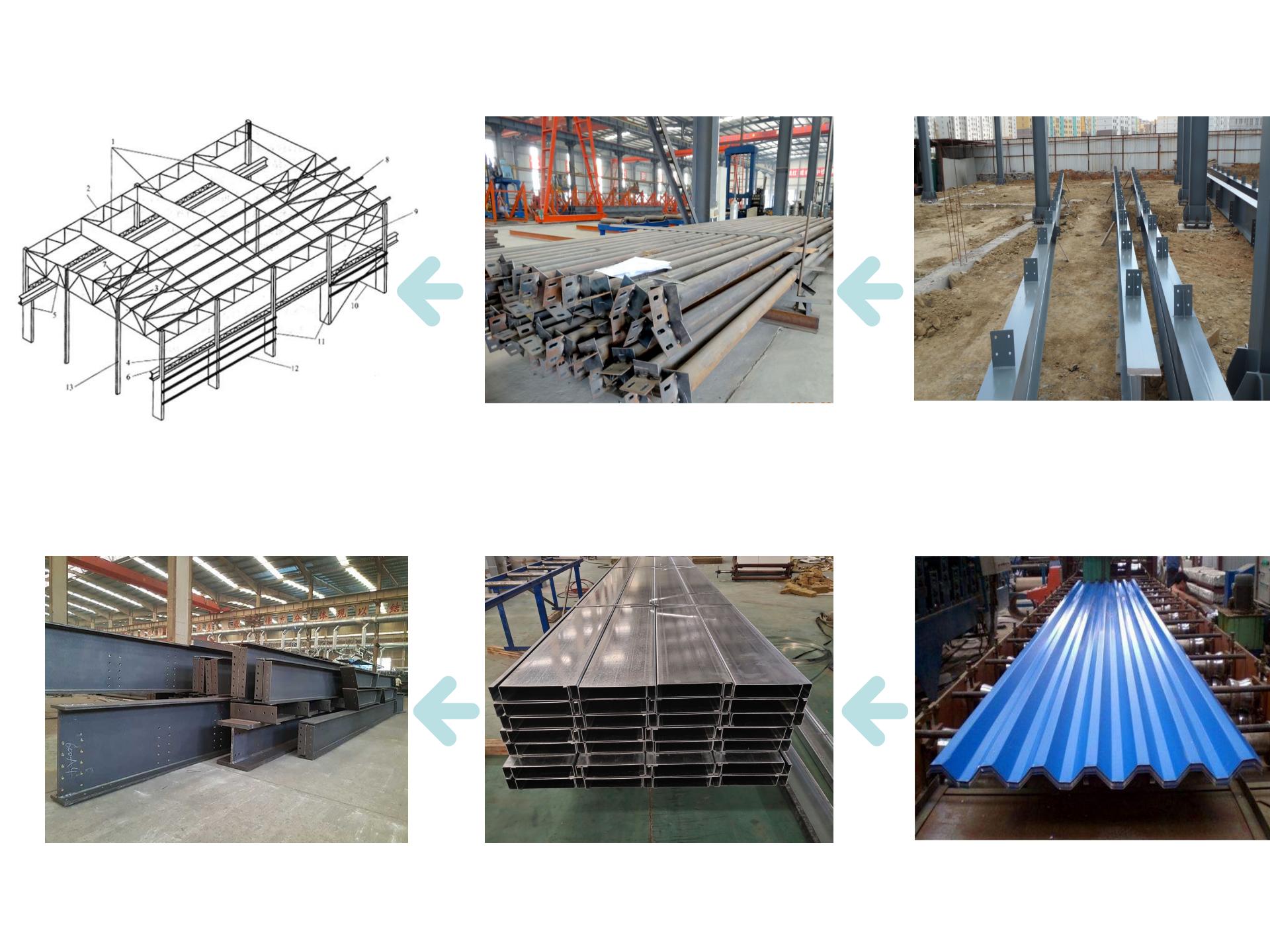

| Назва прадукту: | Металічная канструкцыя сталёвага будынка |

| Матэрыял: | Q235B, Q345B |

| Асноўная рама: | H-вобразная сталёвая бэлька |

| Прагон: | Сталёвая прагонка ў форме C, Z |

| Дах і сцяна: | 1. гафрыраваны сталёвы ліст; 2. сэндвіч-панэлі з мінеральнай ваты; 3. Сэндвіч-панэлі з EPS; 4. сэндвіч-панэлі са шкловалакна |

| Дзверы: | 1. Рулонныя вароты 2. Разсуўныя дзверы |

| Акно: | ПВХ сталь або алюмініевы сплаў |

| Выліўны носік: | Круглая труба з ПВХ |

| Прымяненне: | Усе віды прамысловых майстэрняў, складоў, вышынных будынкаў |

ПРАЦЭС ВЫТВОРЧАСЦІ ПРАДУКЦЫІ

ПЕРАВАГА

Якасць канструкцыйнай сталі

Існуе мноства розных варыянтаў канструкцыйнай сталі. Чым ніжэйшае ўтрыманне вугляроду ў абранай сталі, тым лягчэй яе зварваць. Ніжэйшае ўтрыманне вугляроду азначае больш высокую хуткасць вытворчасці ў будаўнічых праектах, але гэта таксама можа зрабіць матэрыял больш складаным у апрацоўцы. FAMOUS можа прапанаваць рашэнні па канструкцыйнай сталі, якія з'яўляюцца эфектыўнымі і вельмі эфектыўнымі. Мы дапаможам вам вызначыць ідэальны тып канструкцыйнай сталі для вашага праекта. Працэсы, якія выкарыстоўваюцца для праектавання канструкцыйнай сталі, могуць паўплываць на кошт. Аднак канструкцыйная сталь з'яўляецца эканамічна эфектыўным матэрыялам пры правільным выкарыстанні. Сталь - выдатны, вельмі ўстойлівы матэрыял, але ён значна больш эфектыўны ў руках вопытных і добра адукаваных інжынераў, якія разумеюць яе ўласцівасці і патэнцыйныя перавагі. У цэлым, сталь мае велізарную колькасць пераваг для падрадчыкаў і іншых, хто мае намер выкарыстоўваць яе ў прамысловых мэтах. Эксперты выявілі, што нават узмацненне старых будынкаў з дапамогай новых працэсаў зваркі можа значна палепшыць трываласць будынка. Уявіце сабе перавагі выкарыстання прафесійна зваранай канструкцыйнай сталі з самага пачатку для вашага будаўнічага праекта. Тады звяжыцеся з FAMOUS для ўсіх вашых патрэб у зварцы і вырабе канструкцыйнай сталі.

Устойлівасць — гэта здольнасць сталёвага элемента захоўваць сваю першапачатковую раўнаважную форму (стан) пад дзеяннем знешняй сілы.

Страта ўстойлівасці — гэта з'ява, пры якой сталёвы элемент раптоўна змяняе сваю першапачатковую раўнаважную форму пры павелічэнні ціску да пэўнай ступені, што называецца няўстойлівасцю. Некаторыя сціснутыя тонкасценныя элементы таксама могуць раптоўна змяніць сваю першапачатковую раўнаважную форму і стаць няўстойлівымі. Такім чынам, гэтыя сталёвыя кампаненты павінны мець здольнасць падтрымліваць сваю першапачатковую раўнаважную форму, гэта значыць мець дастатковую ўстойлівасць, каб гарантаваць, што яны не будуць няўстойлівымі і не пашкоджанымі ў зададзеных умовах выкарыстання.

Нестабільнасць прыціскной планкі звычайна ўзнікае раптоўна і мае вельмі разбуральныя наступствы, таму прыціскная планка павінна мець дастатковую ўстойлівасць.

Карацей кажучы, для забеспячэння бяспечнай і надзейнай працы сталёвых элементаў, яны павінны мець дастатковую апорную здольнасць, гэта значыць мець дастатковую трываласць, калянасць і ўстойлівасць, якія з'яўляюцца трыма асноўнымі патрабаваннямі для забеспячэння бяспечнай працы кампанентаў.

Металаапрацоўка — гэта стварэнне металічных канструкцый шляхам рэзкі, гнутця і зборкі. Гэта працэс з дабаўленай вартасцю, які ўключае стварэнне машын, дэталяў і канструкцый з розных сыравінных матэрыялаў.

Дэпазіт

Будынкі са сталёвых канструкцыйОперны тэатр размешчаны ў паўночнай частцы Сіднэя. Гэта знакавы будынак Сіднэя, спраектаваны дацкім архітэктарам Ёрнам Утзонам. Сіднэйскі оперны тэатр выкарыстоўвае складаную сталёвую канструкцыю, якая апіраецца на дах з шматслаёвай складзенай канструкцыяй, каб ён мог вытрымліваць нагрузку, не парушаючы крывалінейнасці першапачатковага дызайну.

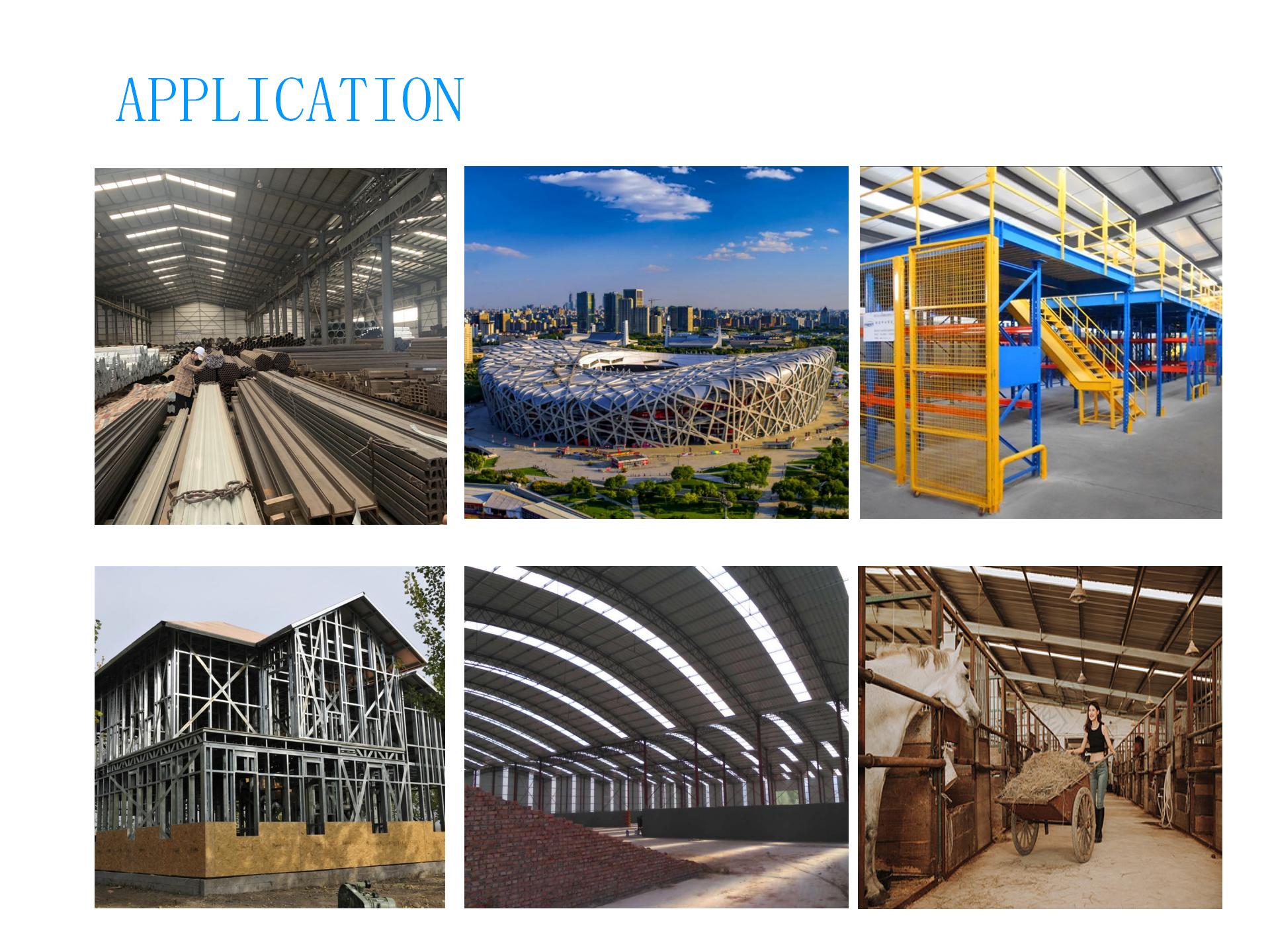

ПРЫМЯНЕННЕ

1. Зніжэнне выдаткаў

Выраб сталёвых канструкцыйпатрабуюць меншых выдаткаў на вытворчасць і гарантыю, чым традыцыйныя будаўнічыя канструкцыі. Акрамя таго, 98% сталёвых канструкцыйных кампанентаў можна паўторна выкарыстоўваць у новых збудаваннях без зніжэння механічных уласцівасцей.

2. Хуткая ўстаноўка

Дакладная апрацоўка кампанентаў для вырабу сталёвых канструкцый павялічвае хуткасць мантажу і дазваляе выкарыстоўваць праграмнае забеспячэнне для маніторынгу кіравання для паскарэння працэсу будаўніцтва.

3. Здароўе і бяспека

Кампаненты для вырабу сталёвых канструкцый вырабляюцца на заводзе і бяспечна мантуюцца на месцы прафесійнымі мантажнымі брыгадамі. Вынікі фактычных даследаванняў даказалі, што сталёвая канструкцыя з'яўляецца найбольш бяспечным рашэннем.

Падчас будаўніцтва вельмі мала пылу і шуму, бо ўсе кампаненты вырабляюцца загадзя на заводзе.

4. Будзьце гнуткімі

Выраб сталёвых канструкцый можа быць зменены ў адпаведнасці з будучымі патрэбамі, нагрузкай, доўгім пашырэннем, які адпавядае патрабаванням уладальніка, і іншыя канструкцыі не могуць быць дасягнуты.

ПРАЕКТ

Прамысловыя будынкі:Дом са сталёвых канструкцыйчаста выкарыстоўваюцца на заводах або складах. Дом са сталёвых канструкцый — гэта зборны модуль, апрацоўка, выраб, транспарціроўка і мантаж якога вельмі хуткія. Акрамя таго, ён лёгкі і мае высокую грузападымальнасць і ўдаратрываласць, што можа забяспечыць бяспеку і стабільнасць завода. Акрамя таго, сталёвую канструкцыю можна разабраць і перабудаваць у залежнасці ад патрэб, што забяспечвае высокую гнуткасць.

Сельскагаспадарчыя будынкі: Для розных сельскагаспадарчых і садовых культур яны маюць перавагі высокай святлопрапускальнасці, высокай цеплавой эфектыўнасці, энергазберажэння і нізкіх эксплуатацыйных выдаткаў. Прадукт выкарыстоўвае цалкам сталёвы каркас апоры сталёвай канструкцыі дома і прастору канструкцыі без калон, таму апорная здольнасць цяпліцы больш трывалая, стабільная і надзейная, і тое ж самае тычыцца сельскагаспадарчых жывёл.

Грамадскія будынкі: Зараз у многіх высотных будынках або спартзалах выкарыстоўваюцца сталёвыя канструкцыі, якія могуць эфектыўна абараніць будынак ад стыхійных бедстваў і тэхнагенных пашкоджанняў, такіх як землятрусы, пажары і г.д.; сталёвыя канструкцыі не схільныя да карозіі, маюць высокую тэмпературу, вогнеўстойлівасць і простыя ў абслугоўванні; сталёвыя канструкцыі звычайна вырабляюцца з высокатрывалых матэрыялаў, і сама сталь не патрабуе абсталявання для апрацоўкі, таму гэта дазваляе зэканоміць шмат інвестыцый.

Жылыя памяшканні: Характарыстыкі сталёвых канструкцый ствараюць умовы для таго, каб будынак быў лёгкім і празрыстым, што дазваляе рэалізаваць мадэляванне прасторы з вялікім пралётам і лакальнае больш складанае мадэляванне. Гэта танна і энергаэфектыўна.

Платформа прылады: Сыравіна платформы сістэмы сталёвых канструкцый мае добрую пластычную дэфармацыю і пругкасць, і можа мець вялікую дэфармацыю, таму яна можа вельмі добра вытрымліваць нагрузку рухаючай сілы. Гэта таксама дазваляе скараціць тэрмін будаўніцтва і зэканоміць час і працоўную сілу. Узровень механічнай аўтаматызацыі праектавання сістэм сталёвых канструкцый высокі, што дазваляе ажыццяўляць сістэматычную вытворчасць, павышаць эфектыўнасць працы, зніжаць каэфіцыент складанасці інжынернага будаўніцтва і адпавядаць характарыстыкам сучаснага высакахуткаснага эксплуатацыі і аховы навакольнага асяроддзя ў сацыяльна-эканамічным развіцці.

ПРАВЕРКА ПРАДУКЦЫІ

Праверка злучэнняў з'яўляецца важным звяном для забеспячэння ўстойлівасці і бяспекі сталёвых канструкцый. Асноўны змест праверкі ўключае якасць зваркі, якасць балтавых злучэнняў, якасць заклёпачных злучэнняў і г.д. Для выяўлення якасці зваркі можна выкарыстоўваць неразбуральны кантроль і іншыя метады выяўлення; для выяўлення балтавых і заклёпачных злучэнняў неабходна выкарыстоўваць такія інструменты, як дынамаметрычныя ключы, для вымярэнняў і выпрабаванняў.

УПАКОВКА І ДАСТАЎКА

Упакоўка: у адпаведнасці з вашымі патрабаваннямі або найбольш прыдатнай.

Дастаўка:

Выберыце падыходны від транспарту: у залежнасці ад колькасці і вагі сталёвай канструкцыі выберыце адпаведны від транспарту, напрыклад, грузавікі з плоскай платформай, кантэйнеры або судны. Улічвайце такія фактары, як адлегласць, час, кошт і любыя заканадаўчыя патрабаванні да перавозкі.

Выкарыстоўвайце адпаведнае пад'ёмнае абсталяванне: для пагрузкі і разгрузкі сталёвай канструкцыі склада выкарыстоўвайце адпаведнае пад'ёмнае абсталяванне, такое як краны, аўтапагрузчыкі або пагрузчыкі. Пераканайцеся, што выкарыстоўванае абсталяванне мае дастатковую грузападымальнасць для бяспечнай апрацоўкі вагі шпунтавых паляў.

Замацаванне грузу: належным чынам замацуйце ўпакаваны штабель сталёвай канструкцыі на транспартным сродку з дапамогай рамянёў, мацаванняў або іншых прыдатных сродкаў, каб прадухіліць зрушэнне, слізганне або падзенне падчас транспарціроўкі.

МОЦ КАМПАНІІ

Зроблена ў Кітаі, першакласны сэрвіс, найвышэйшая якасць, сусветна вядомы

1. Эфект маштабу: Наша кампанія мае шырокі ланцужок паставак і вялікі сталеліцейны завод, дасягаючы эфекту маштабу ў транспарце і закупках, і становячыся сталеліцейнай кампаніяй, якая аб'ядноўвае вытворчасць і паслугі.

2. Разнастайнасць прадукцыі: Разнастайнасць прадукцыі, любую сталь, якую вы хочаце, можна набыць у нас, у асноўным займаючыся сталёвымі канструкцыямі, сталёвымі рэйкамі, сталёвымі шпунтамі, фотаэлектрычнымі кранштэйнамі, швелернай сталёй, рулонамі з крэмніевай сталі і іншымі вырабамі, што робіць яго больш гнуткім. Выберыце патрэбны тып прадукцыі для задавальнення розных патрэб.

3. Стабільныя пастаўкі: больш стабільная вытворчая лінія і ланцужок паставак могуць забяспечыць больш надзейныя пастаўкі. Гэта асабліва важна для пакупнікоў, якім патрэбныя вялікія аб'ёмы сталі.

4. Уплыў брэнда: большы ўплыў брэнда і большы рынак

5. Абслугоўванне: Вялікая сталеліцейная кампанія, якая аб'ядноўвае налады, транспарціроўку і вытворчасць

6. Цэнавая канкурэнтаздольнасць: разумная цана

*Дашліце электронны ліст на адрас[электронная пошта абаронена]каб атрымаць прапанову па вашых праектах

КЛІЕНТЫ НАВЕДВАЮЦЬ